Product Description

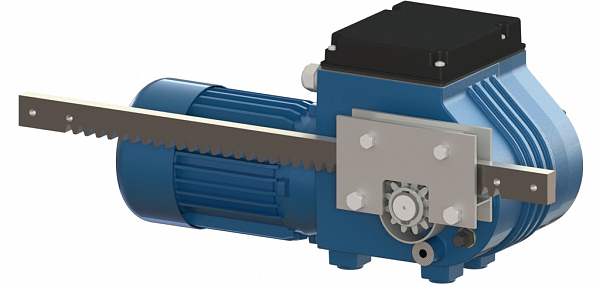

Fixed Lower Backlash Worm Reducers

|

|||

| Related Products | |||

| Our Company | |||

| Ever-power Group specialist in making all kinds of mechanical transmission and hydraulic transmission like: planetary gearboxes, worm reducers, in-line helical gear speed reducers, parallel shaft helical gear reducers, helical bevel reducers, helical worm gear reducers, agricultural gearboxes, tractor gearboxes, auto gearboxes, pto shafts, special reducer & related gear components and other related products, sprockets, hydraulic system, vacuum pumps, fluid coupling, gear racks, chains, timing pulleys, udl speed variators, v pulleys, hydraulic cylinder, gear pumps, screw air compressors, shaft collars low backlash worm reducers and so on. furthermore, we can produce customized variators, geared motors, electric motors and other hydraulic products according to customers’ drawings. We provides a reliable grantee for the product’ s quality by advanced inspection and testing equipment. professional technical team, exquisite processing technology and strict control system. In recent years, the company has been developing rapidly by its rich experience in production, advanced management system, standardized management system, strong technical force. We always adhere the concept of survival by quality, and development by innovation in science and technology. Our Group is willing to work with you hand in hand and create brilliance together! |

|||

|

Material available Low carbon steel, C45, 20CrMnTi, 42CrMo, 40Cr, stainless steel. Can be adapted regarding customer requirements. |

Surface treatment Blacking, galvanization, chroming, electrophoresis, color painting, …

|

Heat treatment High frequency quenching heat treatment, hardened teeth, carbonizing, nitride, … |

|

| Certifications | |||

|

FAQ: Q: Are you trading company or manufacturer ? A: Our group consists in 3 factories and 2 abroad sales corporations. Q: Do you provide samples ? is it free or extra ? Q: How long is your delivery time ? What is your terms of payment ? Q: What is the exact MOQ or price for your product ? If you have another question, please feel free to contact us. |

|||

| Packing & Delivery | |||

| Services Also I would like to take this opportunity to give a brief introduction of our CHINAMFG company: Our company is a famous manufacturer of agriculture gearbox,worm reduce gearbox, PTO shafts, Sprockets ,rollar chains, bevel gear, pulleys and racks in china. We have exported many products to our customers all over the world, we have long-time experience and strong technology support. Some of our customer : -Ø Our Company with over 12 year’s history and 1000 workers and 20 sales. You also can check our website to know for more details, if you need our products catalogue, please contact with us. |

|||

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Marine, Toy, Agricultural Machinery, Car, Wood-Working Machine |

|---|---|

| Function: | Distribution Power, Change Drive Direction, Speed Changing, Speed Reduction |

| Layout: | Wrom |

| Hardness: | Hardened Tooth Surface |

| Installation: | Worm Reducer |

| Step: | Worm Drive |

Ensuring Smooth Operation and Reliability of Greenhouse Gearboxes

Greenhouse gearboxes play a crucial role in maintaining optimal ventilation and shading systems. To ensure their smooth operation and reliability, several factors need to be considered:

- Quality Construction: Opt for gearboxes from reputable manufacturers known for their quality construction. High-quality materials and precision manufacturing contribute to long-term reliability.

- Sealed and Protected Design: Greenhouse environments can be humid and prone to dust and debris. Choose gearboxes with sealed and protected designs that prevent moisture and contaminants from affecting internal components.

- Proper Lubrication: Regular and appropriate lubrication is essential for reducing friction and wear. Choose gearboxes that allow easy lubrication and follow the manufacturer’s recommendations for lubrication intervals and types.

- Maintenance: Implement a regular maintenance schedule for your gearboxes. Inspect for wear, check lubrication levels, and address any issues promptly. Proper maintenance can extend the lifespan of your gearboxes.

- Overload Protection: Some gearboxes come with overload protection features that prevent damage due to excessive force. This ensures the gearbox is not subjected to loads beyond its capacity.

- Testing and Calibration: Ensure that the gearboxes are properly tested and calibrated before installation. This includes verifying gear ratio, speed, and accuracy to guarantee smooth and reliable operation.

- Automation Integration: If your greenhouse uses automation systems, ensure that the gearboxes are seamlessly integrated. Compatibility with control systems and sensors ensures accurate and synchronized operation.

- Professional Installation: Proper installation is essential for the reliable functioning of gearboxes. Hire professionals or follow manufacturer guidelines to ensure correct installation and alignment.

- Training and Education: Provide training to the personnel responsible for operating and maintaining the gearboxes. Proper handling and care can significantly impact the longevity and performance of the gearboxes.

By considering these factors and following best practices for maintenance and operation, greenhouse gearboxes can deliver smooth operation and long-term reliability, contributing to the efficient functioning of greenhouse systems.

Enhancing Precision of Greenhouse Equipment with Gearbox Technology

Greenhouse gearboxes play a significant role in enhancing the precision of various greenhouse equipment and systems:

- Ventilation Systems: Gearbox-controlled ventilation systems allow precise adjustment of louvers and vents. This level of control ensures optimal airflow and temperature regulation, promoting healthy plant growth.

- Shading Systems: Gearboxes are used to operate shading systems that provide protection from excessive sunlight. By adjusting the shading angle with precision, gearboxes prevent overheating and minimize stress on plants.

- Irrigation Systems: Gearbox-driven irrigation systems enable accurate and controlled water distribution. This prevents overwatering or underwatering, which is essential for maintaining plant health and conserving water.

- Temperature Control: Greenhouses equipped with gearbox-controlled heaters and cooling systems can maintain consistent temperatures. Gearboxes ensure precise adjustments based on external conditions, preventing temperature fluctuations.

- Lighting Systems: Some advanced greenhouses use gearboxes to adjust artificial lighting positions. This helps optimize light exposure for plants, promoting photosynthesis and growth.

- Automated Planting Systems: Gearbox-driven automation is utilized in planting and transplanting equipment. The precise movement of these systems ensures accurate spacing between plants, improving crop yield and uniformity.

By incorporating gearbox technology, greenhouse equipment can achieve higher levels of precision, resulting in improved crop quality, resource efficiency, and overall productivity.

Contribution of Greenhouse Gearboxes to Efficient Greenhouse Systems

Greenhouse gearboxes play a vital role in ensuring the efficient functioning of greenhouse systems by enabling precise control over various environmental factors. These gearboxes contribute to efficiency in the following ways:

- Temperature Regulation: Greenhouse gearboxes control the opening and closing of roof vents and sidewall vents. By adjusting the gear ratio, operators can regulate the airflow and temperature inside the greenhouse, preventing overheating and maintaining optimal growing conditions.

- Shading and Light Control: Some greenhouse gearboxes are used to control shading systems that protect plants from excessive sunlight. By adjusting the shading mechanisms, operators can manage light levels, prevent scorching, and create the desired level of illumination.

- Ventilation Management: Ventilation systems are essential for air circulation, which prevents the buildup of humidity and pathogens. Greenhouse gearboxes control the operation of louvers and fans, ensuring proper ventilation and reducing the risk of diseases.

- Precision: The ability to finely tune gear ratios in greenhouse gearboxes allows for precise adjustments in equipment operations. This precision helps maintain consistent and stable environmental conditions, which is crucial for plant growth.

- Energy Efficiency: By automating the opening and closing of vents, shades, and other systems, greenhouse gearboxes optimize energy usage. This prevents unnecessary energy wastage and reduces operational costs.

- Plant Health and Growth: Greenhouse gearboxes create an environment where plants can thrive. They prevent stress on plants due to extreme temperatures or light exposure, resulting in healthier growth, increased yields, and improved crop quality.

In summary, greenhouse gearboxes are integral to greenhouse systems’ efficiency by allowing precise control over temperature, light, and ventilation. They contribute to optimized resource utilization, reduced energy consumption, and ultimately, better plant health and productivity.

editor by CX 2024-03-29