Description

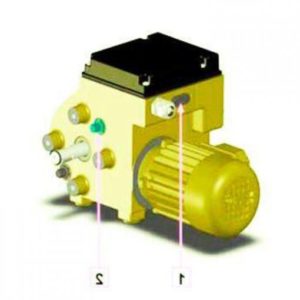

Greenhouse gear reducer

The EP Greenhouse reducer is a concise and lightweight reduction gearbox with a built-in limit switch system that is ideal for assembly of a locally available electric motor. The gear reducer is used in manually-controlled or climate-controlled ventilation and display systems in greenhouses. The quick and easy-to-install EP gearbox is certainly rainproof and windproof. The gear reducer includes a high protection course (IP65) and can be utilized in an ambient temperature of 0-60 °C.

The low-noise gearbox for Greenhouse has a gearwheel transmission and a worm wheel transmission, which are integrated within an aluminum precision housing. The self-braking worm wheel transmitting means that the drive shaft is definitely locked when the reduction gear reducer isn’t running. The completely sealed reduction reducer has an expansion chamber with a diaphragm to keep the gear essential oil at a minimal pressure under all conditions, even at high temps. Thanks to the use of an expansion chamber, the gear motor can be installed in any placement. There are no restrictions, because there is no need for a bleed connect. The sealed reduction gear reducer keeps the gear essential oil of the gearbox in optimal condition because of its entire operating life time. The gearbox is ideal for discontinuous use, working class s3-30%, with a maximum activation period of 25 minutes.

The Gear box reduction gear driver comes with an FT85 motor assembly flange, to which a suitable IEC standard motor can easily be installed (EN 50347).

The Gear box includes a rotating limit switch system with operating switches and circuit breakers (NC contacts) for turning off at the end positions. The limit switch system is installed within an integrated chamber and is definitely enclosed by an impact-resistant plastic material cover. The limit switch system is obtainable and simple to adjust. The limit change system’s maximum switching range can be 40 or 64 revolutions of the drive shaft. The cabling is linked in spring-clip connections. The gear motor comes with an IP68 M16 x 1.5 cable gland (5-9 mm cable) for the cable feed-through.

The geared motor for greenhouse comes with 16 teeth 5/8”x3/8” sprockets, keys and fasteners. The accompanying chain couplings and assembly plates are available as accessories.

Maximum drive torque of 150 Nm or 450 Nm.

Rotational speeds of 3 or 5 rpm for a mains frequency of 50 Hz or 3.6 or 6 rpm for a mains frequency of 60 Hz in case of program of 4-pole electric motor.

Protection class IP65.

Can be used in ambient temperatures of 0-60°C.

Suitable for discontinuous use, operating class s3-30%, maximum activation time 25 moments.

Equipped as regular with 16-tooth galvanised chain coupling 5/8″x3/8″.

FT85 motor assembly flange for installation of IEC regular motor (EN 50347).

Maximum switching selection of limit switch system 40 or 64 revolutions of the drive shaft.

IP68 M16x1.5 cable gland for cable feedthrough (5-9 mm cable).