Product Description

7hp Cultivator Tillers And Cultivators Gear Box For Mini Tiller

Product Description

Tilling Weeding Powert Tiller AA Ditching

Mainly used for:;Tilling,;weeding,;ditching,;ridging,;mulch laying.;

The multifunction mini power tiller.;It is widely used in orchards,;vegetable fields,;mountains and paddy fields,;and it’s very popular among customers.;

| Model | 1WGQ4-90A |

| Overall dimensions(L*W*H); | 1400*900*900mm |

| Weight | ≤60kg |

| Engine brand | DUCAR Power |

| Engine type consumption | Gasoline,;4 stroke,;air cooled |

| Tilling width | 300-870mm |

| Tilling depth | 100-150mm |

| Diameter of the rotary blade | 320mm |

| Displacement | 225cc |

| Handlebar | Reduce shake system with spring(adjustable); |

| Economical Fuel consumption | 10.;5kg/ hm² |

| Productivity | 0.;1-0.;12hm2/(h·m); |

| Clutch | Centrifugal clutch,; Dry type |

| Gear shift | Stepless |

| Operating speed | 0.;7-1m/s |

| Tread | 350mm |

| Rotary blade speed | RPM180 |

| Carburetor choke | Included |

| Electric start | Optional |

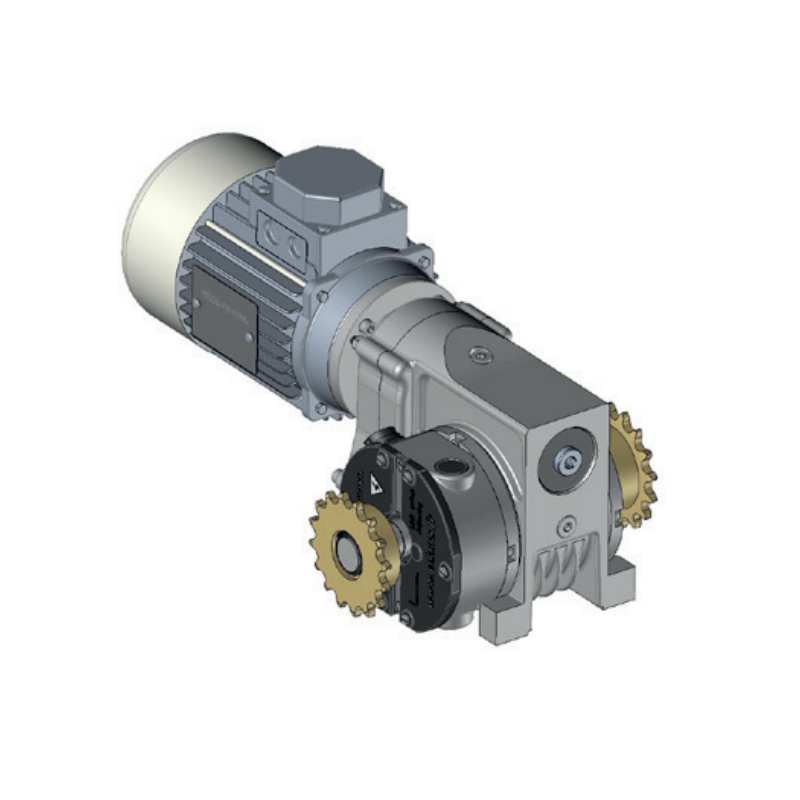

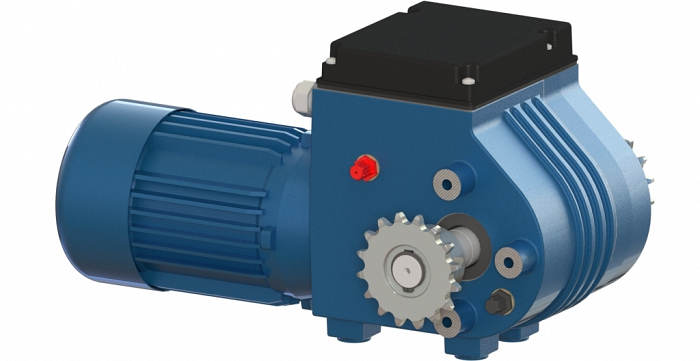

| Power transmission | Full gear |

| Wheel | Solid tire |

| Axis Inner diameter | 23mm |

| Operate method | Walking behind |

| Start method | Manual Recoil |

| Function | Tilling/ Weeding/ Ditching/ Ridging/Seeding/Spraying/Mulch laying |

Applicable:;Plain,;basin,;hill,;mountin country,;greenhouse,;vegetable garden,;orchard,;hard land,;dry land,;sandy land,;loose land,;paddy field

Product details

Big-displacement vertical axis engine,;three-leve air filter,;full gear drive system.;The engine adopts domestic first-class brand with quality assurance.;

Small volume,;light weight,;compact structure.;The whole machine adopts reasonable design,; low fuel consumption,; high efficiency,; strong horsepower,; time-saving and labor-saving.;

Oil bath centrifugal cluth,;simple operation,;strong power and durable quality.;

The gearbox has high strength and strong durability.;

About us

Our company is committed to research,;development,;production and sales of agricultural machinery.;Our main products are multi-functional power tiller,;brush cutter,;power sprayer,;power generator,;water pump,;etc.;The products are mainly sold to Southeast Asia,;Africa,;European and American,;all the export value takes up 85% of the total sales amount each year.;Our core value is provide high-quality products to our customers.;We believe quality is the life of an enterprise.;Welcome to visit us and we it’s hoped that we can build a CHINAMFG relationship in near future.;Thank you for your trust!

Our factory

Packaging & Shipping

FAQ

Q:;Are you a produce factory or trading company?

A:;We are produce company.;

Q:;What is your MOQ?

A:;10 sets.;

Q:;What about your payment term?

A:;T/T,;Western Union,;Paypal.;

Q:;What is the mode of transportation?

A:;By sea.;

Q:;What is the delivery time?

A:; Order amount under 100 sets 7 days.;

Q:;Do you have OEM service?

A:;Yes,;our main business is OEM service.;

Q:;What is the warranty time?

A:;The power tiller warranty time 1 year,;gearbox 3 years.;

| After-sales Service: | Video Guided Maintenance |

|---|---|

| Type: | Rotary Tiller |

| Application Field: | Agriculture |

| Farming Policy: | Dry Cultivating Machinery |

| Power Source: | Gasoline |

| Operation: | Arable Machinery, Movable Operation |

| Customization: |

Available

| Customized Request |

|---|

Factors to Consider When Selecting a Greenhouse Gearbox

Choosing the right greenhouse gearbox for your setup is crucial to ensure optimal performance and functionality. Here are the key factors to consider:

- Load Capacity: Evaluate the weight and resistance of the louvers or other components the gearbox will control. Ensure the gearbox can handle the load without straining or wearing out.

- Gearbox Ratio: Select a gearbox with the appropriate ratio to achieve the desired louver movement based on the motor’s input. The ratio determines how much the louver will open or close per motor rotation.

- Speed Requirements: Consider the speed at which you need the ventilation louvers to open or close. Choose a gearbox that can provide the necessary speed while maintaining precision.

- Automation Compatibility: Determine whether the gearbox can be easily integrated into your greenhouse’s automation system. Compatibility with sensors, controllers, and other automation components is essential for efficient operation.

- Accuracy and Precision: Look for a gearbox that offers accurate and precise position control. This ensures that the louvers can be adjusted to the exact desired position for optimal ventilation control.

- Environmental Conditions: Consider the environmental conditions within the greenhouse, including temperature and humidity. Choose a gearbox that can withstand these conditions without compromising performance or durability.

- Installation and Maintenance: Evaluate the ease of installation and maintenance of the gearbox. Access for maintenance and the availability of replacement parts are important considerations.

- Customization: Determine if the gearbox can be customized to suit the specific layout and requirements of your greenhouse. Customization options allow for a tailored solution that fits your needs.

- Budget: Compare the cost of the gearbox with its features and capabilities. Choose a gearbox that provides the best value for your budget while meeting your requirements.

By carefully considering these factors, you can select the right greenhouse gearbox that will enhance the efficiency and effectiveness of your greenhouse ventilation and shading systems.

Emerging Trends in Greenhouse Gearbox Technology: Remote Control and More

As technology continues to advance, several emerging trends are shaping the development of greenhouse gearbox technology:

- Remote Control and Automation: One notable trend is the integration of remote control and automation features. Many modern greenhouse gearboxes are designed to be remotely operated and controlled through digital interfaces. This allows growers to adjust settings, monitor equipment performance, and make real-time changes from a distance.

- IoT Integration: The Internet of Things (IoT) is making its way into greenhouse operations. Gearboxes can be equipped with sensors that collect data on factors like temperature, humidity, and airflow. This data is then transmitted to a central system, enabling precise adjustments based on real-time conditions.

- Smart Algorithms: Advanced gearboxes are incorporating smart algorithms that can analyze environmental data and adjust equipment settings accordingly. For example, a gearbox can automatically open or close vents based on temperature and humidity thresholds, optimizing the growing environment.

- Energy Efficiency: Greenhouse gearbox technology is also evolving to enhance energy efficiency. Variable speed drives and optimized control algorithms help minimize energy consumption while maintaining optimal conditions for plant growth.

- Modular and Scalable Systems: Some gearbox manufacturers are developing modular and scalable systems that can be easily expanded as the greenhouse operation grows. This flexibility allows growers to adapt their equipment to changing needs without significant disruptions.

Overall, the integration of remote control, automation, data analytics, and energy efficiency features is shaping the future of greenhouse gearbox technology. These trends are aimed at providing growers with more precise control over their operations and improved resource management.

Greenhouse Gearbox and its Role in Greenhouse Operations

A greenhouse gearbox is a type of gearbox specifically designed for use in greenhouse operations. It is used to control various systems and equipment within a greenhouse, such as ventilation systems, shading systems, and temperature control mechanisms. These gearboxes help automate and regulate environmental conditions in the greenhouse to create an optimal growth environment for plants.

The gearbox is integrated into the mechanisms that operate roof vents, sidewall vents, and other systems that control airflow, temperature, and shading. By adjusting the gear ratio, greenhouse operators can control the opening and closing of vents and shades, allowing for precise management of temperature, humidity, and light levels inside the greenhouse.

Greenhouse gearboxes are crucial for maintaining ideal growing conditions and ensuring the health and productivity of plants. They contribute to energy efficiency, improved plant quality, and optimized resource usage in greenhouse operations.

editor by CX 2024-04-03