Product Description

Product Description

|

Products |

Gear rack |

|||

|

Precision grade |

DIN5, DIN6, DIN7, DIN8, DIN10 |

|||

|

Material |

C45 steel, 304SS, 316SS, 40CrMo, nylon, POM |

|||

|

Heat treatment |

High frequency,Quenching/Carburization, Teeth hardened |

|||

|

Surface treatment |

Zinc-plated,Nickle-plated,Chrome-plated,Black oxide or as you need |

|||

|

Application Machine |

Precision cutting machines. Lathes machine Milling machines Grinders machine Automated mechanical systems Automated warehousing systems. |

|||

|

Produce Machine |

CNC engine lathe CNC milling machine CNC drilling machine CNC grinding machine CNC cutting machines Machining center |

|||

|

Workstyle |

Execution is more preferred than empty talk. |

|||

|

Stock Gear Rack Type |

Specification |

Color |

|

Helical gear rack |

M1 15*15*1000mm |

White |

|

M1.5 19*19*1000mm |

White |

|

|

M2 24*24*1000mm |

White |

|

|

M3 29*29*1000mm |

White |

|

|

M4 39x39x1000mm |

White |

|

|

Spur gear rak |

M1 15*15*1000mm |

Black |

Rack Assembly

To assemble connected racks more smoothly, 2 ends of a standard rack would add half tooth which is convenient for next half tooth of next rack to be connected to a complete tooth. The following drawing shows how 2 racks connect and tooth gauge can control pitch position accurately.

With regards to connection of helical racks, it can be connected accurately by opposite tooth gauge.

1. When connecting racks, we recommend lock bores on the sides of rack first, and lock bores by the sequence of the foundation. With assembling the tooth gauge, pitch position of racks can be assembled accurately and completely.

2. Last, lock the position pins on 2 sides of rack; the assembly is completed.

Test

Use Coordinate Measuring Machine to test the precision and hardness of gear rack and pinion

Packaging & Shipping

Small quantity: We will use carton box.

Big quantity: We will use wooden cases.

Company Profile

ZheJiang Haorongshengye Electrical Equipment Co., Ltd.

1. Was founded in 2008

2. Our Principle:

“Credibility Supremacy, and Customer First”

3. Our Promise:

“High quality products, and Excellent Service”

4. Our Value:

“Being Honesty, Doing the Best, and Long-lasting Development”

5. Our Aim:

“Develop to be a leader in the power transmission parts industry in the world”

|

6.Our services: |

1).Competitive price |

|||

|

2).High quality products |

||||

|

3).OEM service or can customized according to your drawings |

||||

|

4).Reply your inquiry in 24 hours |

||||

|

5).Professional technical team 24 hours online service |

||||

|

6).Provide sample service |

||||

Main products

Machines

Exbihition

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Manufacturing Method: | Hobbing |

| Toothed Portion Shape: | Spur Gear |

| Material: | Steel |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

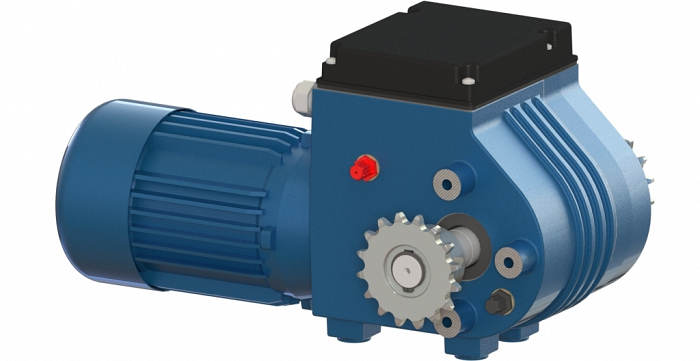

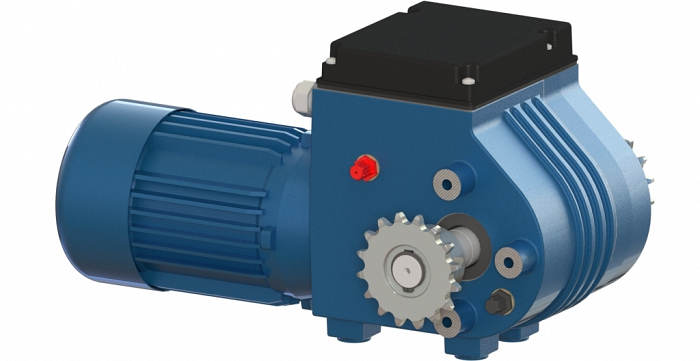

Versatile Applications of Greenhouse Gearboxes in Automation

Greenhouse gearboxes offer versatile solutions for a range of automation tasks within greenhouse operations. Their precise and reliable operation makes them suitable for various applications:

- Ventilation Systems: Greenhouse gearboxes are commonly used to control the opening and closing of ventilation windows, ensuring optimal air circulation and temperature regulation.

- Shading Systems: These gearboxes enable precise adjustment of shading systems, allowing for effective control of light levels to protect plants from excessive sunlight.

- Roll-Up Sidewalls: Gearboxes can automate roll-up sidewalls, enabling easy modification of the greenhouse’s height and ventilation based on environmental conditions.

- Irrigation Systems: Gearboxes are employed in automating irrigation systems to adjust water distribution and ensure even watering of plants.

- Screen Systems: Greenhouse gearboxes contribute to the deployment and retraction of screens that regulate light, humidity, and temperature.

- Temperature and Humidity Control: Gearboxes aid in automating louvers, vents, and dampers to maintain optimal greenhouse conditions.

- Seedling Transplanting: Gearboxes can be integrated into systems that automate the movement of seedlings, ensuring efficient planting.

- Curtain Systems: These gearboxes are used in controlling curtains that partition the greenhouse into sections, optimizing plant growth conditions.

- Climate Control: Gearboxes are essential for managing complex climate control systems that require precise adjustments for temperature, humidity, and CO2 levels.

- Lighting Systems: Greenhouse gearboxes may contribute to the movement of adjustable lighting systems to maintain consistent light exposure for plants.

Due to their reliability, accuracy, and ability to handle various tasks, greenhouse gearboxes play a pivotal role in streamlining and enhancing greenhouse automation processes.

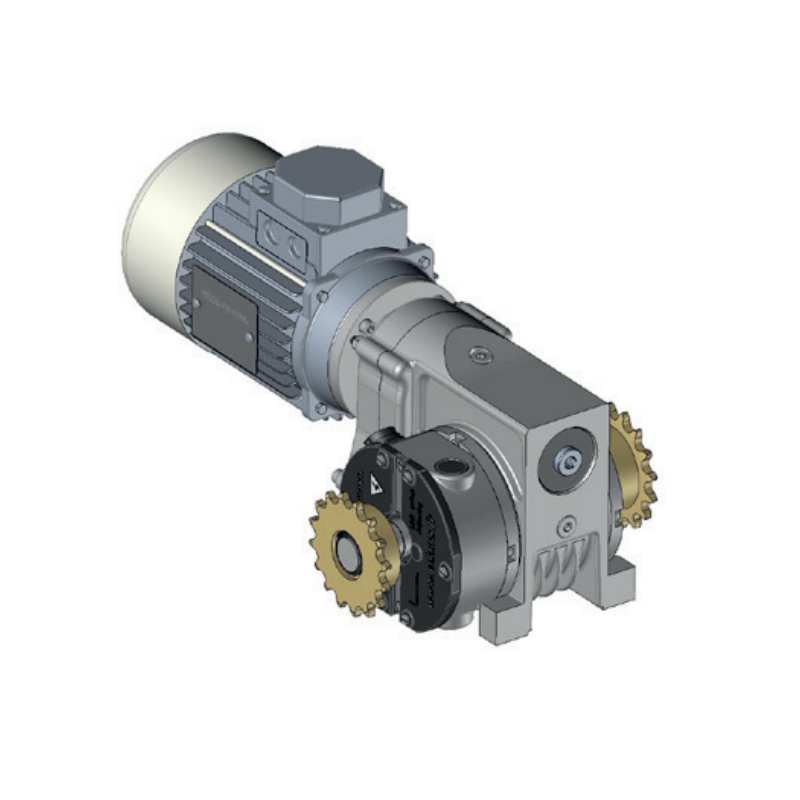

Optimizing Performance of Greenhouse Gearboxes through Gear Ratios

Gear ratios play a crucial role in enhancing the performance of greenhouse gearboxes by influencing various aspects of their operation:

- Speed and Torque: Gear ratios determine the relationship between the speed of input and output shafts. By selecting appropriate gear ratios, greenhouse gearboxes can achieve the desired balance between speed and torque, ensuring efficient operation of ventilation systems, louvers, and other components.

- Precision: The right gear ratios enable precise control over the movement of various greenhouse mechanisms. This is crucial for maintaining accurate positioning of vents, shades, and other elements to regulate temperature and lighting.

- Energy Efficiency: Properly chosen gear ratios ensure that the gearbox operates within its optimal range, reducing unnecessary energy consumption. This is especially important for automation systems that require continuous adjustment.

- Response Time: Gear ratios influence the response time of the gearbox in adjusting greenhouse components. Well-matched gear ratios allow for quick and smooth transitions, ensuring rapid adaptation to changing conditions.

- Load Distribution: Gear ratios help distribute loads evenly across various components, preventing strain and wear. This extends the lifespan of both the gearbox and the connected mechanisms.

In essence, gear ratios enable greenhouse gearboxes to tailor their performance to the specific needs of the environment, ensuring optimal conditions for plant growth while maximizing efficiency and longevity.

Greenhouse Gearbox and its Role in Greenhouse Operations

A greenhouse gearbox is a type of gearbox specifically designed for use in greenhouse operations. It is used to control various systems and equipment within a greenhouse, such as ventilation systems, shading systems, and temperature control mechanisms. These gearboxes help automate and regulate environmental conditions in the greenhouse to create an optimal growth environment for plants.

The gearbox is integrated into the mechanisms that operate roof vents, sidewall vents, and other systems that control airflow, temperature, and shading. By adjusting the gear ratio, greenhouse operators can control the opening and closing of vents and shades, allowing for precise management of temperature, humidity, and light levels inside the greenhouse.

Greenhouse gearboxes are crucial for maintaining ideal growing conditions and ensuring the health and productivity of plants. They contribute to energy efficiency, improved plant quality, and optimized resource usage in greenhouse operations.

editor by CX 2024-04-02