Product Description

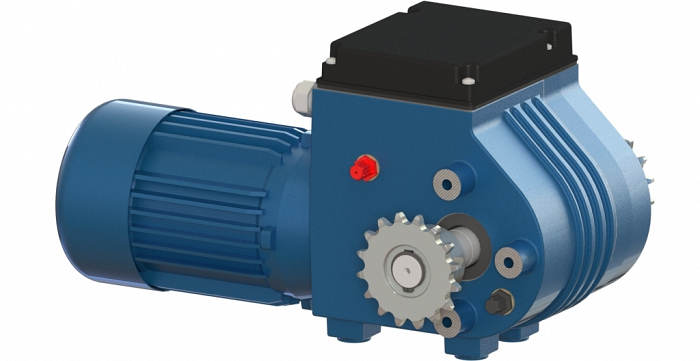

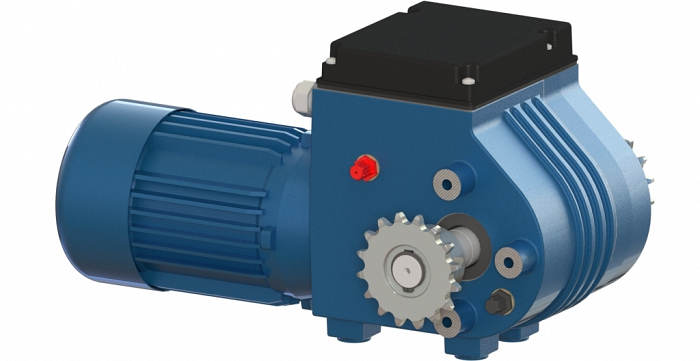

BKM Helical Gearbox Speed ReducerBKM series high efficiency hypoid helcial gearbox is a new generation of product developed by our company fuses the advanced technology both at home and aborad the mounting dimension of BKM the same with NMRV series worm reducers,adpot gear transmission used for reference SEW helical gearbox structure to improve transmission efficiency, Solved NMRV worm reduer transmission efficiency low,service life short and esc problems in industrial developing,BKM is the product of saving energy and green enviromental products. Uses of BKM Reducer? The BLM reducers are applied in fields like tuning instruments, elevators, escalators, conveyor belts, medical equipment, power transmission systems, and security CHINAMFG to name a few. NMRV Worm Speed Gear Reducer Worm Reducer For Paper Cutting Machine Worm Gear Drive Screw Actuator Worm Gear Slew Drive

|

|||

| Our Company | |||

| Ever-power Group specialist in making all kinds of mechanical transmission and hydraulic transmission like: planetary gearboxes, worm reducers, in-line helical gear speed reducers, parallel shaft helical gear reducers, helical bevel reducers, helical worm gear reducers, agricultural gearboxes, tractor gearboxes, auto gearboxes, pto shafts, special reducer & related gear components and other related products, sprockets, hydraulic system, vacuum pumps, fluid coupling, gear racks, chains, timing pulleys, udl speed variators, v pulleys, hydraulic cylinder, gear pumps, screw air compressors, shaft collars low backlash worm reducers and so on. furthermore, we can produce customized variators, geared motors, electric motors and other hydraulic products according to customers’ drawings. We provides a reliable grantee for the product’ s quality by advanced inspection and testing equipment. professional technical team, exquisite processing technology and strict control system. In recent years, the company has been developing rapidly by its rich experience in production, advanced management system, standardized management system, strong technical force. We always adhere the concept of survival by quality, and development by innovation in science and technology. Our Group is willing to work with you hand in hand and create brilliance together! |

|||

|

Material available Low carbon steel, C45, 20CrMnTi, 42CrMo, 40Cr, stainless steel. Can be adapted regarding customer requirements. |

Surface treatment Blacking, galvanization, chroming, electrophoresis, color painting, …

|

Heat treatment High frequency quenching heat treatment, hardened teeth, carbonizing, nitride, … |

|

| Certifications | |||

|

FAQ: Q: Are you trading company or manufacturer ? A: Our group consists in 3 factories and 2 abroad sales corporations. Q: Do you provide samples ? is it free or extra ? Q: How long is your delivery time ? What is your terms of payment ? Q: What is the exact MOQ or price for your product ? If you have another question, please feel free to contact us. |

|||

| Packing & Delivery | |||

| Services Also I would like to take this opportunity to give a brief introduction of our CHINAMFG company: Our company is a famous manufacturer of agriculture gearbox,worm reduce gearbox, PTO shafts, Sprockets ,rollar chains, bevel gear, pulleys and racks in china. We have exported many products to our customers all over the world, we have long-time experience and strong technology support. Some of our customer : -Ø Our Company with over 12 year’s history and 1000 workers and 20 sales. You also can check our website to know for more details, if you need our products catalogue, please contact with us. |

|||

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Helical Gear |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

Versatile Applications of Greenhouse Gearboxes in Automation

Greenhouse gearboxes offer versatile solutions for a range of automation tasks within greenhouse operations. Their precise and reliable operation makes them suitable for various applications:

- Ventilation Systems: Greenhouse gearboxes are commonly used to control the opening and closing of ventilation windows, ensuring optimal air circulation and temperature regulation.

- Shading Systems: These gearboxes enable precise adjustment of shading systems, allowing for effective control of light levels to protect plants from excessive sunlight.

- Roll-Up Sidewalls: Gearboxes can automate roll-up sidewalls, enabling easy modification of the greenhouse’s height and ventilation based on environmental conditions.

- Irrigation Systems: Gearboxes are employed in automating irrigation systems to adjust water distribution and ensure even watering of plants.

- Screen Systems: Greenhouse gearboxes contribute to the deployment and retraction of screens that regulate light, humidity, and temperature.

- Temperature and Humidity Control: Gearboxes aid in automating louvers, vents, and dampers to maintain optimal greenhouse conditions.

- Seedling Transplanting: Gearboxes can be integrated into systems that automate the movement of seedlings, ensuring efficient planting.

- Curtain Systems: These gearboxes are used in controlling curtains that partition the greenhouse into sections, optimizing plant growth conditions.

- Climate Control: Gearboxes are essential for managing complex climate control systems that require precise adjustments for temperature, humidity, and CO2 levels.

- Lighting Systems: Greenhouse gearboxes may contribute to the movement of adjustable lighting systems to maintain consistent light exposure for plants.

Due to their reliability, accuracy, and ability to handle various tasks, greenhouse gearboxes play a pivotal role in streamlining and enhancing greenhouse automation processes.

Managing Variations in Temperature and Environmental Conditions with Greenhouse Gearboxes

Greenhouse gearboxes play a crucial role in maintaining optimal conditions for plant growth by managing variations in temperature and environmental factors. Here’s how they contribute:

- Ventilation Control: Greenhouse gearboxes are used to regulate the opening and closing of vents and louvers. This helps control temperature by allowing hot air to escape and cool air to enter when needed.

- Shading Systems: Some gearboxes control shading systems that provide shade to prevent excessive sunlight and heat buildup during the day. These systems can be adjusted to provide the right amount of shade based on the outdoor conditions.

- Heating Systems: Gearboxes can control heating systems, ensuring that the greenhouse remains warm and frost-free during colder periods. They adjust the intensity of heating equipment based on temperature sensors.

- Cooling Systems: In warmer climates, greenhouse gearboxes manage cooling systems such as fans and misting systems. They adjust the speed and operation of these systems to maintain a consistent temperature.

- Humidity Control: Some gearboxes are involved in managing humidity levels by controlling misting or humidification systems. These systems help maintain the appropriate level of moisture in the air.

The ability to adjust these factors with precision allows greenhouse operators to create a controlled environment that promotes healthy plant growth, regardless of external temperature and weather conditions.

Industries Utilizing Greenhouse Gearboxes for Controlled Environments

Greenhouse gearboxes find extensive applications in various industries that require controlled environments for optimal plant growth and productivity:

- Agriculture and Horticulture: Greenhouses are commonly used for cultivating crops, flowers, and ornamental plants. Gearboxes are essential for automating ventilation, shading, and irrigation systems, enabling precise control over growing conditions.

- Research and Experimentation: Research institutions and educational facilities utilize greenhouses to study plant physiology, genetics, and growth under specific conditions. Gearboxes assist in creating controlled environments for conducting experiments and analyzing plant responses.

- Food Production: The agriculture industry employs greenhouses to grow vegetables, herbs, and fruits year-round. Gearboxes help optimize temperature, humidity, and light levels, contributing to higher yields and faster growth rates.

- Floriculture: Greenhouses are crucial for producing flowers and floral arrangements. Gearboxes enable automated processes that ensure consistent quality and aesthetics in floral products.

- Nurseries: Plant nurseries use greenhouses to propagate and grow young plants before transplanting them to outdoor settings. Gearboxes aid in maintaining ideal conditions for the healthy development of seedlings.

- Pharmaceuticals: Pharmaceutical companies may use controlled environments to cultivate medicinal plants for research and production. Gearboxes assist in creating the necessary conditions for optimal plant growth and active compound development.

Overall, greenhouse gearboxes play a pivotal role in supporting industries that rely on controlled environments to achieve specific plant-related goals and outcomes.

editor by CX 2024-03-29