Product Description

Cm-Dh-L65 High Sales PLA Pbat Degradable OPP film blowing machine gearbox

Product Description

CHINAMFG mainly focusing on R&D, manufacturing of high-end film blowing machines, provides cost-effective blown film machines and professional engineering film blowing service to markets. The typical film blowing machines CHINAMFG provides are: single layer blown film machines, AB double layer film blowing machines, ABA/ABC 3 layers blown film machines, ABCDE/ABCBA 5 layers film blowing machines, specialized agricultural films blowing machines and super wide industrial films making machines for materials of LDPE/LLDPE/PP/EVA/PLA/PBAT etc.

LDPE twin head blown film machine

1.Brief introduction:

This type of film blowing machine is mainly for making T-shirt bags, flat bags etc.

2.Features

* Bimetal screw & barrel,L/D ratio 30:1

* Standard type manual operation screen changer

* PID + CHINAMFG CHINAMFG control system both for extruder & extrusion die

* Spiral extrusion die with dual die insert in difference dimension & gap

* Dual lip LD air cooling ring + single lip HD air ring insert

* High effective air cooling blower with air volume adjustor

* Wooden stripe stabilizer + wooden stripe type bubble basket with gussetung device

* SMF type semi-manual surface friction winder + standard steel winding reel

Product Parameters

|

Model |

Roller width(mm) |

Film width(mm) |

Film output (kg/hr) |

Main motor(Kw) |

Die head(mm) |

Cooling Blower(Kw) |

Take up motor(Kw) |

|

CM-DH-L Twin head blown film machine(LDPE/LDPE+LLDPE),0.02-0.12mm |

|||||||

|

CM-DH-L45 |

400 |

150-300 |

30-50 |

15 |

60 |

0.75 |

0.37 |

|

CM-DH-L55 |

500 |

200-400 |

40-80 |

22 |

80 |

1.5 |

0.37 |

|

CM-DH-L65 |

650 |

300-550 |

60-110 |

37 |

120 |

2.2 |

0.37 |

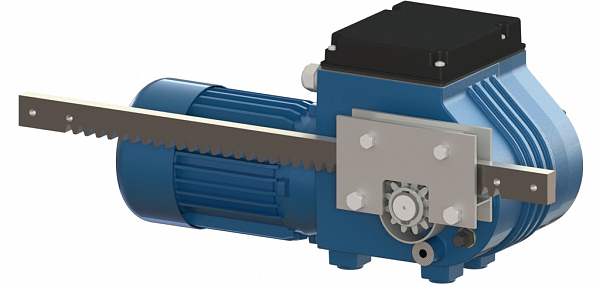

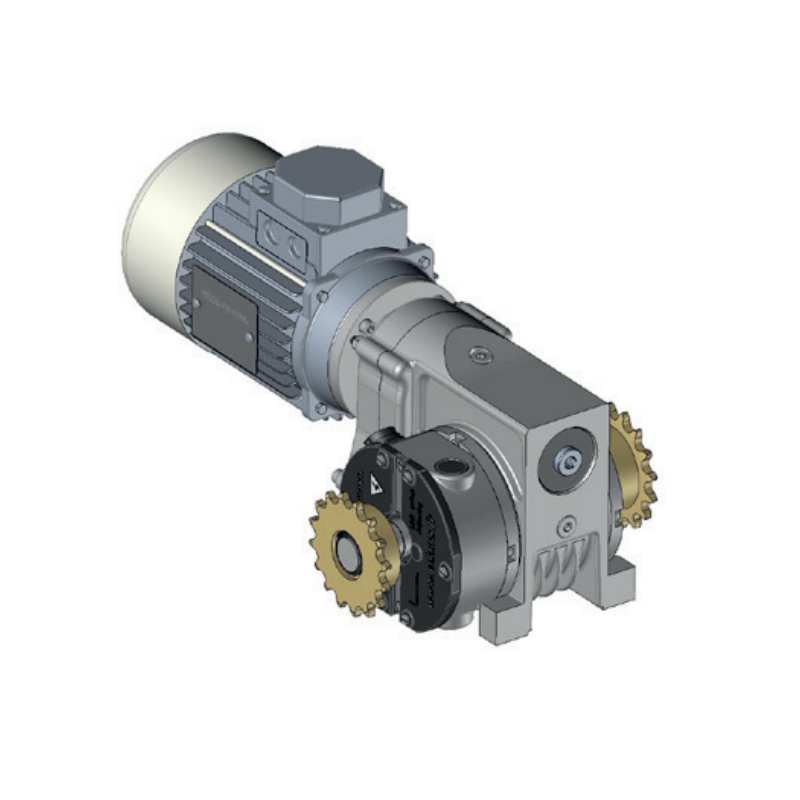

Detailed Photos

Company Profile

FAQ

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME

* CHINAMFG is original manufacturer.

* If you interested in our products and we can fulfill your request , you may pay a visit to CHINAMFG Factory.

* The meaning of visiting supplier, since seeing is believing, CHINAMFG Machinery with own manufacture and developed& research team, we can send you engineers and make sure the high efficiency after-sales service.

SEE CHINAMFG MACHINE HOW TO ENSURE THE QUALITY

* In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

* Each component before assembly needs strict control by inspecting personnel.

* Each assembly is in charge by a master who has working experience for more than 15 years

* After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers’ factory

THE AFTER-SALE SERVICE OF CHINAMFG MACHINERY

* After finishing the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

* After the commissioning, we will package the equipment by the standard export package for shipment.

* According to the customer’s request, we can arrange our engineers to customers’ factories to do the installation and training.

* Engineers, sales managers, and after-sales service managers will form an after-sales team, online and offline, to follow the customers’ project.

IF YOU WOULD LIKE TO KNOW MORE ABOUT US, PLEASE CONTACT US

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Local Service Available |

|---|---|

| Warranty: | 2 Years |

| Type: | Multi-Layer Co-extrusion Film Blowing Machine |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Ensuring Smooth Operation and Reliability of Greenhouse Gearboxes

Greenhouse gearboxes play a crucial role in maintaining optimal ventilation and shading systems. To ensure their smooth operation and reliability, several factors need to be considered:

- Quality Construction: Opt for gearboxes from reputable manufacturers known for their quality construction. High-quality materials and precision manufacturing contribute to long-term reliability.

- Sealed and Protected Design: Greenhouse environments can be humid and prone to dust and debris. Choose gearboxes with sealed and protected designs that prevent moisture and contaminants from affecting internal components.

- Proper Lubrication: Regular and appropriate lubrication is essential for reducing friction and wear. Choose gearboxes that allow easy lubrication and follow the manufacturer’s recommendations for lubrication intervals and types.

- Maintenance: Implement a regular maintenance schedule for your gearboxes. Inspect for wear, check lubrication levels, and address any issues promptly. Proper maintenance can extend the lifespan of your gearboxes.

- Overload Protection: Some gearboxes come with overload protection features that prevent damage due to excessive force. This ensures the gearbox is not subjected to loads beyond its capacity.

- Testing and Calibration: Ensure that the gearboxes are properly tested and calibrated before installation. This includes verifying gear ratio, speed, and accuracy to guarantee smooth and reliable operation.

- Automation Integration: If your greenhouse uses automation systems, ensure that the gearboxes are seamlessly integrated. Compatibility with control systems and sensors ensures accurate and synchronized operation.

- Professional Installation: Proper installation is essential for the reliable functioning of gearboxes. Hire professionals or follow manufacturer guidelines to ensure correct installation and alignment.

- Training and Education: Provide training to the personnel responsible for operating and maintaining the gearboxes. Proper handling and care can significantly impact the longevity and performance of the gearboxes.

By considering these factors and following best practices for maintenance and operation, greenhouse gearboxes can deliver smooth operation and long-term reliability, contributing to the efficient functioning of greenhouse systems.

Contribution of Greenhouse Gearboxes to Energy Efficiency

Greenhouse gearboxes play a significant role in enhancing energy efficiency in greenhouse operations through various mechanisms:

- Precision Control: Gearboxes allow for precise and controlled adjustments of ventilation, shading, and other systems. This prevents unnecessary energy consumption by ensuring that these systems operate only when needed.

- Optimized Automation: With the use of automated greenhouse gearboxes, systems can be programmed to respond to changing environmental conditions. This prevents overuse of resources and ensures that energy-intensive operations are carried out efficiently.

- Synchronization: Gearboxes enable synchronization of various greenhouse components, such as fans, louvers, and shades. This synchronization ensures that these components work together seamlessly, reducing energy waste due to conflicting actions.

- Minimized Heat Loss: Gearboxes control the opening and closing of vents and windows. By optimizing ventilation, gearboxes help maintain optimal temperatures inside the greenhouse without excessive heat loss, reducing the need for additional heating.

- Efficient Shading: Automated shading systems operated by gearboxes can regulate the amount of sunlight entering the greenhouse. This prevents overheating, reduces the need for cooling, and saves energy.

- Consistent Irrigation: In some cases, gearboxes control irrigation systems. Efficient irrigation management prevents water wastage and helps plants receive the right amount of moisture, reducing the need for excess watering and related energy consumption.

Overall, greenhouse gearboxes contribute to energy efficiency by intelligently managing and optimizing various greenhouse systems, resulting in reduced energy consumption, lower operational costs, and environmentally sustainable practices.

Automation of Ventilation and Shading Systems with Greenhouse Gearboxes

Greenhouse gearboxes play a vital role in automating ventilation and shading systems, enhancing the efficiency of greenhouse operations:

- Ventilation Systems: Gearboxes are integrated into automated ventilation setups to control the opening and closing of windows, louvers, and vents. By adjusting the gear ratios, these gearboxes enable precise regulation of airflow based on factors such as temperature, humidity, and CO2 levels. This automation helps maintain optimal growing conditions and prevents excessive heat buildup.

- Shading Systems: Gearboxes are utilized in automated shading systems that provide protection from intense sunlight. These systems include retractable screens or shading curtains that can be controlled based on light intensity and time of day. Greenhouse gearboxes allow gradual adjustments to the shading level, preventing sudden changes that could stress plants. By automating shading, gearboxes contribute to maintaining consistent light levels and preventing overheating.

The automation of ventilation and shading systems using greenhouse gearboxes reduces the need for manual intervention, especially in large-scale greenhouse operations. Growers can program the gearboxes to respond to environmental conditions, ensuring that plants receive the right amount of fresh air and light without requiring constant monitoring.

editor by CX 2024-03-28